Planning and evaluating resilient supply chains

From efficiency to resilience

For a long time, companies focused primarily on efficiency and cost savings in their supply chains. Inventories were reduced and the “just-in-time” principle was introduced, meaning that components are only delivered when needed. However, this practice made supply chains more vulnerable to disruptions and interruptions.

Current challenges for global supply chains

Current events such as the COVID-19 pandemic, the war in Ukraine, and the blockage of the Suez Canal by the Ever Given have demonstrated how vulnerable globally networked supply chains are. One concrete example is the collapse of a bridge in the port of Baltimore, which temporarily brought shipping to a complete standstill. This led to significant declines in the delivery of car parts, which is reflected in a so-called resilience curve—a tool that graphically depicts performance drops and recovery times after disruptions.

Development of quantitative assessment methods

The study presents metrics that can be used to quantitatively assess the resilience of a supply chain. This includes analyzing the extent and duration of a disruption as well as the effectiveness of countermeasures such as warehousing or supplier diversification.

Measuring the effectiveness of resilience measures

A particular methodological innovation in this work lies in the development of metrics that can specifically measure the improvement in resilience achieved through concrete measures. This makes it possible to objectively compare different strategies and evaluate their effectiveness. Companies can thus identify cost-effective measures to make their supply chains more resilient. This methodology is flexible and can also be applied to other areas such as hospitals or entire economies.

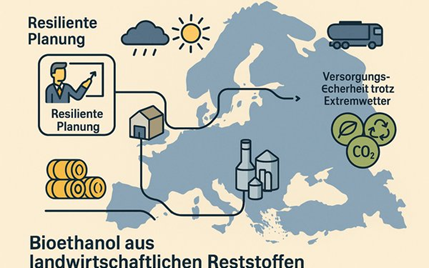

Application of resilience methodology to bioeconomic supply chains: Resilient supply chain modeling for a sustainable bioeconomy

Building on these methodological foundations for assessing and improving supply chain resilience, the methodology developed was applied to bioeconomic supply chains in a follow-up study. These supply chains face particular challenges due to climate-related fluctuations in the availability of renewable raw materials and thus offer an ideal field of application for resilient planning approaches.

Fluctuating raw material availability as a challenge

Bioeconomic supply chains that process biogenic raw materials and replace fossil-based products are particularly vulnerable to weather-induced fluctuations in raw material availability—as is the case with straw, for example. These fluctuations are increasing in frequency and intensity as a result of climate change, posing a major challenge to the security of supply of bio-based products, which are essential for sustainable development.

An integrated two-stage approach

The publication “Encounter the Unforeseen: Resilient Supply Chain Modeling for a Sustainable Bioeconomy” takes a two-step approach to map both the producer and consumer perspectives in an integrated model:

- The first step involves resilient strategic planning for a European bioeconomy supply chain that produces bioethanol as a fuel substitute from straw. This anticipates possible representative fluctuations in the availability of the raw material. Supply is optimized while ensuring a minimum supply level from the consumer's perspective and economic efficiency on the producer's side.

- In the second step, the actual resilience of the system to unpredictable, random fluctuations in raw material availability is assessed. The model analyzes both the economic and ecological impacts. A particular focus is placed on security of supply from the consumer's perspective, which is a central concern in resilience research.

Methodological features

The methodology combines strategic planning that takes uncertainties into account with simulation of possible unforeseen events for validation purposes. In addition, environmental assessments using life cycle assessment are integrated to comprehensively capture the ecological impacts. The resilience curve introduced in the first study is used for the quantitative assessment of resilience, which demonstrates the advantages of the presented approach based on an improved curve compared to deterministic planning. Specifically, two resilience measures are taken into account: (1) adaptation of production capacities to the underlying representative supply scenarios and (2) expansion of storage capacities. Both measures significantly improve the curve and enhance security of supply even in the event of unforeseen disruptions.

Key findings

Research shows that bioeconomic supply chains designed for high resilience from a consumer perspective often require larger production and storage capacities. This leads to higher environmental impacts from infrastructure and operations. However, these additional burdens are significantly offset by the benefits of replacing fossil-based products in most environmental indicators. The model thus contributes to promoting a sustainable and resilient bioeconomy that combines economic and environmental goals.