Contact Person

Contact information:

Address:

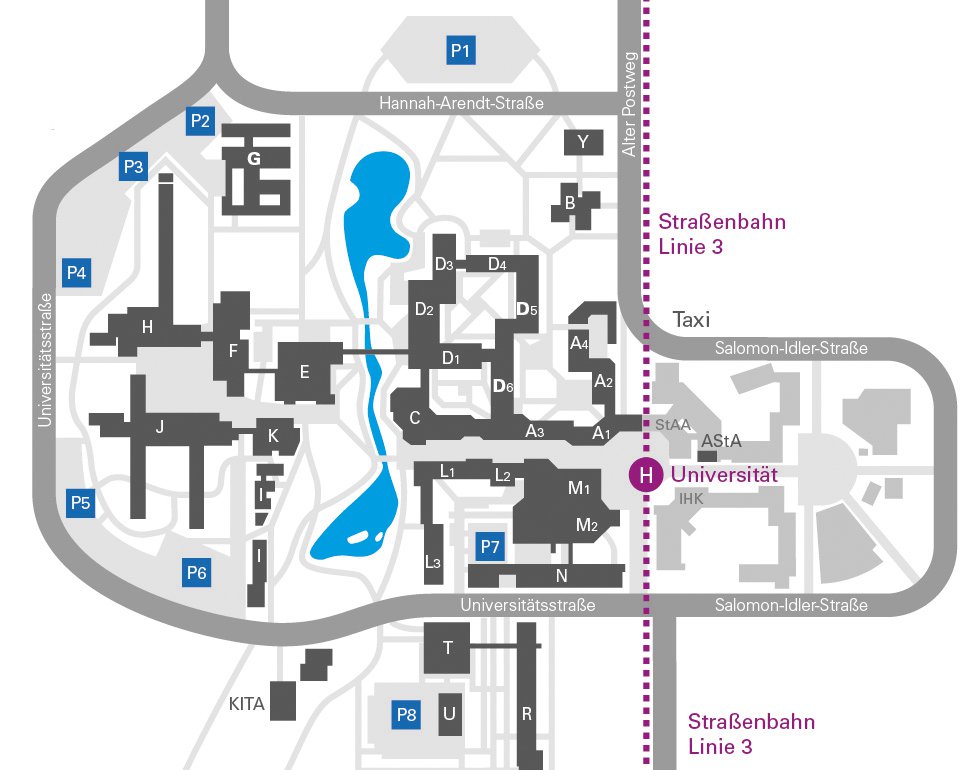

Experimentalphysik IV

Institut für Physik

Universität Augsburg

86135 Augsburg

Phone: +49 821 598 -3402 (Office)

Fax: +49 821 598 -3425

E-Mail: sekretariat_ep4@physik.uni-augsburg.de (Office)

Building: R