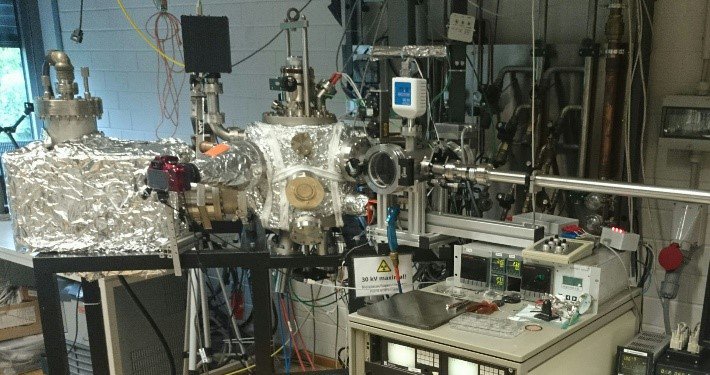

Molecular-beam epitaxy setup for thermoelectrics

This device is mainly used for the preparation of thermoelectric thin films, such as the Skutterudites CoSb3 or CeFe4Sb12 on substrates with a maximum size of (30 x 30) mm2. The device is equipped with four effusion cells. Two cells are high temperature cells (up to 1700 °C), which are used for evaporating low vapor pressure materials (currently iron Fe and cobalt Co). The other two cells, which are used for high vapor pressure elements (currently antimony Sb and bismuth Bi) can be operated at temperatures of up to 700 °C. By using heat shields above the effusion cells, the radiative heating of the sample holder is minimized. Therefore, a sample temperature of less than 50 °C can be maintained during the deposition process. Furthermore, the temperature of the rotatable sample holder can be controlled to temperatures of up to 400 °C by using a SiC heater. By using a RHEED system (STAIB Instruments), the deposition process can be monitored in situ.

A load lock is used for sample transfer, and therefore a base pressure of 2∙10-10 mbar can be maintained. During the deposition process, the pressure is in the range of 10-9 to 10-7 mbar, depending on the temperatures used. Usual deposition rates are in the range of 0.01 to 5 Å/s.